Having better supply chain visibility is crucial to track the supplier network activity accurately and accomplish supply chain management (SCM). In this article, you will learn what Supply Chain Visibility (SCV) is, why it is so important, and how to increase supply chain visibility. In addition, we will discuss some next-gen technologies to accelerate supply chain digital transformation.

How to Increase Supply Chain Visibility with Next-gen Technologies

Overview

The efficiency of a company’s supply chain is one of the most critical aspects in determining its ability to generate income. It also serves to manage costs and continually meet customer expectations.

According to a study, 79% of companies with high-performing supply chains achieve significantly faster than average revenue growth. However, many companies still struggle with supply chain operations, because they simply require monitoring and visibility capabilities that they don’t have.

Supply chain management is often very complicated for even the smallest organizations. This is especially the case if they must include multiple vendors and manufacturing processes along the way. However, despite its complexity, understanding what happens to the supply chain at each stage of the process is critical to running a business efficiently.

Surprisingly, only a meager 6% of companies report complete end-to-end visibility of their supply chains. 15% only have visibility during production. Consequently, when major problems arise and the supply chain is disrupted, it is very difficult for a business to diagnose and remedy what it cannot see.

In this post, you will learn What is Supply Chain Visibility (SCV), Why SCV is more important now than ever, and how you can optimize the supply chain process and achieve better supply chain visibility. In addition, we will discuss some next-gen technologies to accelerate the digital transformation of the supply chain.

What is Supply Chain Visibility (SCV)?

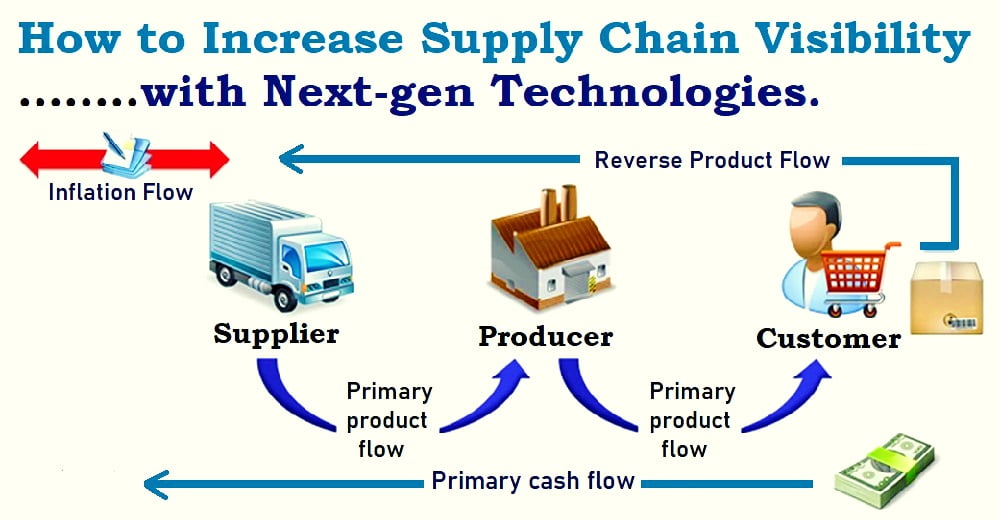

The term “Supply Chain Visibility (SCV)” relates to knowing what is happening at all stages of a company’s supply chain.

Supply chain visibility is the ability for a company to observe and access all shipping events, transactions, and other data throughout its supply chain.

To have true end-to-end supply chain visibility, a business must track individual components, sub-assemblies, and final products through each process in the chain. This ranges from moving a product from the supplier to logistics, transportation, and distribution to the final consumer. The more visibility and more data a company has in its chain, the better.

Supply chain visibility requirements vary widely depending upon the industry. In some cases, monitoring and tracking of individual components are needed, while in others, tracking is at the batch level.

Why is Supply Chain Visibility Important?

Supply chain visibility provides many competitive advantages. It improves worker efficiency and productivity, reduces cycle times, and provides better customer experience and satisfaction.

These days, companies are driven to be more agile and responsive than ever. This is because supply chains are becoming more customer-centric due to the ability of customers to purchase almost anything at any time.

The goal of supply chain visibility is to gain advanced insights on how your supply chain operates and determine what you need to do to align your supply chain to meet customer demands while mitigating disruptions and minimizing risk.

Achieving complete supply chain visibility makes meeting these demands more achievable. At the same time, it improves the overall customer experience.

Supply chain visibility provides organizations with real-time access to the data they need to successfully run their businesses. This information enables them to plan ahead with greater precision based on updated shipping statuses. In turn, companies have the potential to achieve maximum inventory efficiency, reducing warehousing costs as a result.

Finally, overall supply chain visibility helps mitigate risk more effectively. It also prevents order errors and minimizes interruptions. All this results in a better experience for the final consumer.

How to Increase Supply Chain Visibility: The Ultimate Guide

The lack of agility and flexibility of logistics operations to respond to urgent demands as well as the lack of technological solutions to manage and implement new strategies, cause supply chain failure and disruptions. In this context, supply chain visibility is critical.

To increase supply chain visibility, the supply chain must be more resilient, agile, and autonomous. To achieve this, you need to adopt creative marketing ideas with greater transparency of each of the processes and operations. Ideally, you should know at any time where the products are and when they will arrive.

The complexities of the supply chain must be eliminated, defining the essential steps to guarantee operational continuity. For this, it is necessary to rely on the systems and processes used. Which must be efficient and with the least possible functional and technical impact on the environment.

In addition, to achieve supply chain visibility, the company should share essential information with all interested parties. Members of the supply chain, both internal and external, must have sufficient capacity to see and share it, even smaller and geographically remote suppliers that use traditional processes.

Another point to take into account is the ability to react immediately to unforeseen events. The sooner you will react, the easier it will limit or avoid adverse effects on the operation.

A consequence of the lack of visibility in the company is the erroneous assertiveness when making predictions about production or coordinating with suppliers when buying merchandise, which directly impacts the performance of the supply chain. For this reason, it is important to analyze the reports, metrics, or objectives, perhaps using a technological tool, in order to manage supply in terms of demand.

Without defining the market to which your product or service is directed, you will not be able to understand the customer or know their needs or preferences. It is very important to analyze and segment your supply chains in order to offer your customers something that they really value, which also helps to manage the inventory that you require every day.

The relationship between supply and demand must always be balanced in order to ensure the availability of your merchandise and meet the expectations and realities of your customers’ demands. Good management requires knowing how to identify and classify your inventory, in order to synchronize the stock and avoid economic losses.

Organizing the transport of merchandise can be a costly and difficult process if you do not have the necessary management skills. To avoid inconvenience and improve the supply chain, it is important to plan and control shipments and their routes. What many companies choose to do is hire the services of a transportation company.

Depending on your business, if you need international or even multimodal transport, you will have to analyze the most efficient and economical way to store and transport the merchandise. Much of this is the decision regarding the warehouse whether you use shared warehouses or, in the case of an international business, a customs logistics warehouse. This can be the key to having the flexibility you need in terms of demand and the location of suppliers and customers.

Don’t resist change! Think carefully about investing the resources you can in the use and exploitation of technology. Selecting the right tool can facilitate the control you have over the entire process, from inventories, supplies, or shipments, generating a quick and positive return on investment for the company.

After the correct development of these processes, the visibility of the supply chain will allow solving any problem facilitating decision making, which eliminates or reduces the risk of orders that are processed incorrectly, incompletely, or late. In addition, the cost of corrective measures will decrease and it will be possible to better analyze and understand past incidents to gain operational efficiency for the future.

In this way, business agility and external collaboration will be fostered, in turn promoting innovation, which translates into improved service levels, reduced costs, more competitiveness, and greater value generation.

Next-gen Technologies to Accelerate Supply Chain Digital Transformation

As the world becomes increasingly interconnected and consumer demands continue to rise, the stakes have never been higher. As a result, many companies have shifted their emphasis to new and creative marketing ideas and supply chain visibility solutions.

Supply chain digital transformation is proven to increase business performance, drive growth, reduce risk, and optimize costs, addressing both short-term improvements and a strategic long-term vision.

The digital transformation of the supply chain requires strong alignment between next-gen technologies and supply chain strategy to structure an effective business environment and accelerate overall digital supply chains.

These are some of the key next-generation technologies that will improve supply chain visibility and achieve supply chain digital transformation

Internet of Things

The Internet of Things is an effective way to track and authenticate products and shipments, and monitor product storage conditions using the Global Positioning System (GPS) and other technologies. This enhances quality management throughout the supply chain.

With supply chain monitoring units constantly connected to the cloud, companies can now use IoT technology to achieve complete visibility. By using accurate, fast, and secure data logging services, companies can also employ Big Data. Some uses for this are tracking products in transit, observing temperature and humidity conditions, or staying up-to-date on traffic patterns during transportation.

Read here:

2. Internet of Things (IoT) in Industrial Automation

Artificial intelligence

Artificial intelligence technology amplifies important decisions by using cognitive predictions and recommendations about optimal actions.

AI technology helps manufacturers with potential impacts across different scenarios in terms of time, cost, and revenue. It can help improve the overall performance of the supply chain.

Artificial intelligence and machine learning can help companies assess whether their cargo is at risk of mishaps. With this data, the appropriate departments can make better judgments about the response to the problem, such as redirection of deliveries. The ability to track assets throughout the supply chain using AI helps prevent waste and limit inventory loss.

Read Also: Top 10 AI Technologies You Need to Know

Blockchain Technology

Blockchain can substantially improve supply chains. It enables faster and more profitable product delivery, increases product traceability, strengthens partner coordination, and facilitates access to flexible financing lines.

In addition, blockchain technology can better manage supply chains by documenting date, location, price, quality, and certification, as well as other relevant data.

The availability of this data can improve the traceability of materials and reduce counterfeiting and losses from the underground market. Blockchain also increases the visibility and compliance of outsourced manufacturing.

Read here: Blockchain Technology: Advantages and Disadvantages

Robotic Process Automation

Visibility in the supply chain is key to successful automation and greater resilience. One of the technology trends that is driving this benefit is robotic process automation (RPA).

By 2023, 50% of warehouse activities will use RPA technology and big data analytics that will enable warehouse optimization, increasing capacity by 20%, and cutting order processing time in half.

Many companies are planning to use RPA technology to improve their supply chain visibility and optimize the efficiency of inventory and warehouse management in the next three years.

In the case of the supply chain, the priority is to invest in critical infrastructure to improve performance, decrease operational risk and improve resilience.

Read Also:

2. 10 Examples of Robotic Process Automation Use Cases